John F. Wood Centre

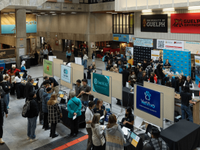

The John F. Wood Centre, housed within the Lang School of Business and Economics, supports innovative and entrepreneurial-minded students at the University of Guelph. Students in all disciplines—whether at the undergraduate or graduate level, in arts, engineering, science, business, or beyond—can access experiential learning opportunities, mentorship, and venture support to help develop their ideas and skills.

In our collaborative space, we offer a dynamic environment where students can build their entrepreneurial skills through practical experiences and programs that emphasize creativity, problem-solving, and entrepreneurial thinking. By nurturing these skills, we help shape the next generation of business leaders poised to make a positive impact in the world. At the John F. Wood Centre, we champion entrepreneurial spirit, business as a force for good, and sustainable prosperity. Simply put – we bring ideas to life!

- 175+ Companies

- Launched through our Hub Incubator

- 250+ Student Entrepreneurs

- Supported with funding, office space and mentorship

- Innovative MakerSpace

- Technology, equipment and resources to support student innovation

- Supporting U of G student's ideas

- Through our innovative and cutting edge progamming

News & Announcements

"As a student it is hard to find a space where I have access and support to bring my creative ideas to life. The Wood Centre welcomed me with open arms and supported me in making creative components to my school and personal projects like a t-shirt for a competition I was entering. They had access to tools I would never be able to afford at this point in my life and offered mentorship. I felt like I had found a community that made my school year a lot more fulfilling and personal. It can be hard to find direct mentorship and connection when there are so many students on campus and the Wood Centre provides that and so much more! I am already planning some projects I want to work on next year and am always telling my family and friends about how incredible this place is. I call it Guelphs hidden gem!"

- Samantha Heard, Bachelor of Engineering Student