Room 174: Water Supply and Treatment

Pre-filtration: Three large aggregate filters complete with timer activated automatic backwash valves filter the incoming well water. The University provides this facility with untreated water drawn from three wells located on campus. While the water quality is exceptionally good it has a tendency to become dirty from the distribution network of pipes on a regular basis. In an effort to maintain the best water quality possible we pre-filter this water prior to piping it to each aquatic research room or ECAR system.

Waste water treatment: Waste water is returned from the research portions of the facility to a sump pit in this room. The water level is monitored by a Miltronics ultrasonic level sensor. This sensor controls two submersible Myers pumps, one is on normal power the other is on emergency power. Water levels in this pit are maintained and alarmed at preset levels. Water leaves the facility for the sanitary sewer after passing two six bulb UV sterilizers.

Cold Glycol Generation: Two Carrier™ refrigeration units are used to chill glycol for the plate heat exchangers found in each research room. These chillers are set up for lead /lag operation with one on emergency power while the other is on normal power. Glycol is currently chilled to -7.5°C. These chillers are alarmed by Argus™ but are controlled by their own internal system.

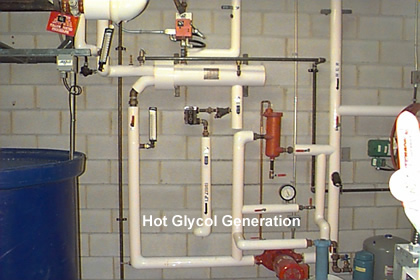

Hot Glycol Generation: There are two shell and tube steam heat exchangers used to heat glycol for the same plate heat exchangers. Glycol is currently warmed to 60°C. This system is under the control of the Argus™ system.

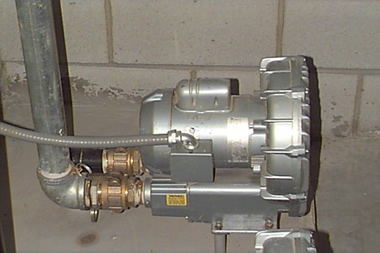

Regenerative air blowers: Three one HP Gast regenerative air blowers are used to provide aeration for fish tanks. Provision has been made to add a fourth air blower should the need arise. Argus™ controls the operation of these blowers two function at all times with a third as back-up. The system alternates blowers to provide even use. Argus has a pressure sensor located on the main line to monitor and alarm this system.

Marine water mixing station: The station comprises three 1 m³ plastic tanks, a 3 hp pump, a pressure switch and expansion tank. The level in the tanks is monitored by a level switch.

High pressure air: On-Campus Central Air is used to provide instrument air for the level sensors located in the research room sumps. Air is backed up by a single high pressure air compressor. At this time no air pressure sensor is located within this system.

Also located in this room is the Motor Control Center, and the recirculation and water treatment system for General Holding, Room 160.