Department of Food Science

Intensive courses on every aspect of cheese making.

Upcoming courses:

Cheese Safety and Quality Assurance - February 23 - March 15 (online)

Introduction to Cheesemaking Technology - April 27 - May 1, 2026 (in person)

The longest running ice cream course in Canada

Upcoming courses:

Dec. 7th - 11th, 2026 (tentative)

Half-day workshops - make different varieties of beer under expert guidance.

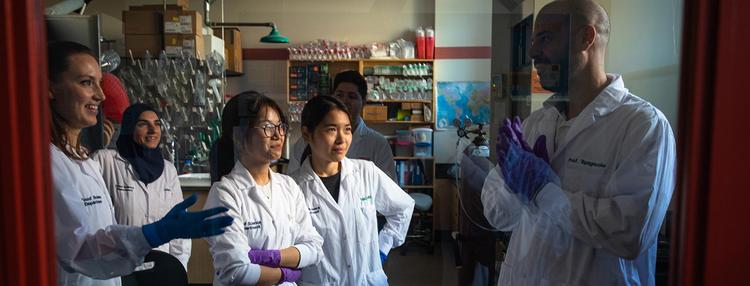

Advancing food production, science and safety.

U of G's Department of Food Science is a global leader in research, education and industry outreach. Our students, graduates and faculty apply the disciplines of chemistry, physics and microbiology to the processing and product development of safe and healthy foods.

Programs in food science and safety

Global leaders in food science and safety.

Faculty within the U of G's Department of Food Science work collaboratively with external partners and organizations to enhance the quality and safety of food. For example, the Canadian Research Institute for Food Safety (CRIFS) provides expert advice that is keeping the world safe from the next pandemic.

Connect with food innovation experts and world-class facilities.

The Guelph Food Innovation Centre (GFIC) offers research services to the food industry that are crucial in driving safety, quality, functionality, and cost-effectiveness needed for products to be competitive in the marketplace.