AI Unlocks Secrets of Aging in Everyday Plumbing

AI-driven deep learning transforms aging analysis of crucial infrastructure, enhancing longevity.

A Groundbreaking Approach to Pipe Degradation

Peering beneath the surface, it's a world of pipes - a hidden network that silently ages and degrades over time, impacting our daily lives and resources. Almost 24% of the water we supply is lost through leakage and pipe failure, an unseen crisis that drains our precious resources and inflates utility bills. Picture this: what if we could predict and prevent potential mishaps in systems we depend on, long before the actual failure occurs? This groundbreaking study revolutionizes how we understand the aging and degradation of cross-linked polyethylene (PEX-a) pipes, which are commonly used for transporting potable water and in radiant heating and cooling systems. Harnessing the power of advanced AI and spectral imaging, this fascinating discovery opens a pathway not just for safer water systems, but also for countless applications in medical diagnostics, archaeology, and beyond. It paves the way to a future where we can extend the life of infrastructure and predict failures before they occur, ultimately improving the quality of life and efficiency across various sectors.

School of Physics

Unravelling the Complexities of Piping

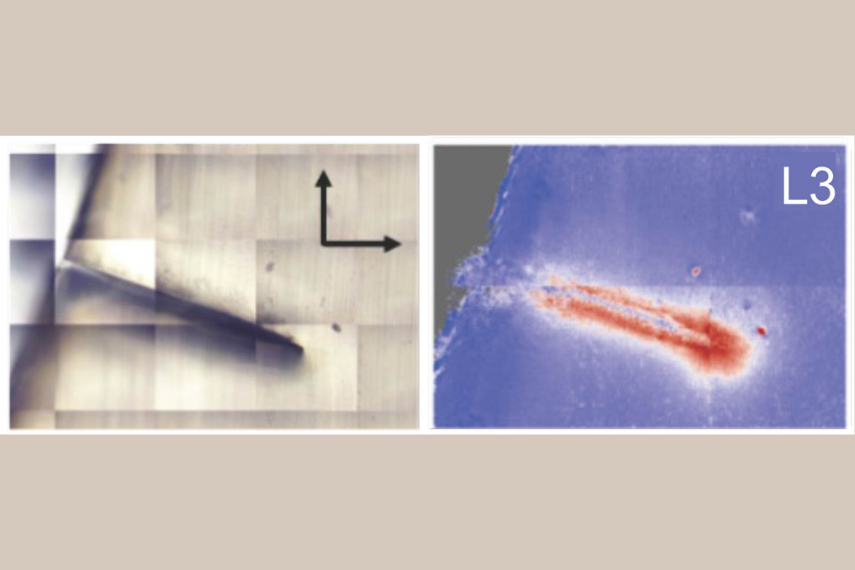

PEX-a pipes are exposed to cleaning agents (like chlorine), UV light, and varying temperatures during their use, which causes degradation over time. To analyse the effects of these stresses and the potential service lifetimes of PEX-a pipes hyperspectral infrared (IR) imaging can be used. This technique provides the possibility to capture high-resolution images of the pipes. However, capturing a huge amount of detail makes the analysis quite a puzzle to solve. The data corresponding to an IR spectrum carries large amounts of information about the physical and chemical properties of the pipe and degradation processes. But imagine trying to interpret a complex piece of art where each color represents a different chemical reaction. This is how it is when these images show different chemical reactions happening all at once, like a canvas filled with myriad hues. Plus, these reactions do not all occur in the same location within the pipe. It is like each section of the pipe is painting its own unique picture!

Harnessing AI to Predict and Prevent

To address this issue, Dr. John Dutcher, from the Department of Physics, and his research group trained an artificial neural network β-variational autoencoder (β-VAE) on a large dataset of PEX-a pipe IR images to make sense of this vast and intricate data. β-VAE is a type of AI model specifically designed to sort through large amounts of information and identify main parameters describing the data. When applied to a series of IR images of PEX-a pipes, the trained model identifies distinct factors of aging and degradation. After the model has been trained, it significantly enhances the analysis process and provides insights into the nature of crack formation and propagation in PEX-a pipes. The results also underscore the potential of deep learning in analyzing complex hyperspectral data, opening the door to important applications in other fields, such as biomedical imaging.

Predicting Failures: From Pipes to Preservation

“Through this research, we gain an extraordinary tool that provides us with the ability to understand the underlying mechanisms of pipe failures. This type of deep learning analysis can help to guide our actions in various fields, from the pipes that circulate water in our houses to the preservation of our cultural heritage, and even to the diagnosis of medical conditions. This type of research is not just pushing the boundaries of what is possible, it is redefining them," said Dutcher.

This story was written by Kasra Ghasemi as part of the Science Communicators: Research @ CEPS initiative. Kasra is a PhD candidate in the School of Engineering under Dr. Syeda Humaira Tasnim and Dr. Shohel Mahmud. His research focus is on developing innovative solutions to poor packaging systems and conventional refrigeration methods and their contributions to food waste and global warming – a Latent Heat Thermal Energy Storage system with micro-scale capsules.

Funding Acknowledgement: The research is financially supported by Natural Sciences and Engineering Research Council of Canada (NSERC) through the Collaborative Research and Development Grant. The research is performed in collaboration with HeatLink, a Calgary-based company, which makes plastic pipes for domestic and industrial water transport and heating applications.

Reference: M. Grossutti et al., “Deep Generative Modeling of Infrared Images Provides Signature of Cracking in Cross-Linked Polyethylene Pipe,” ACS Appl. Mater. Interfaces, vol. 15, no. 18, pp. 22532–22542, May 2023, doi: 10.1021/acsami.3c02564.